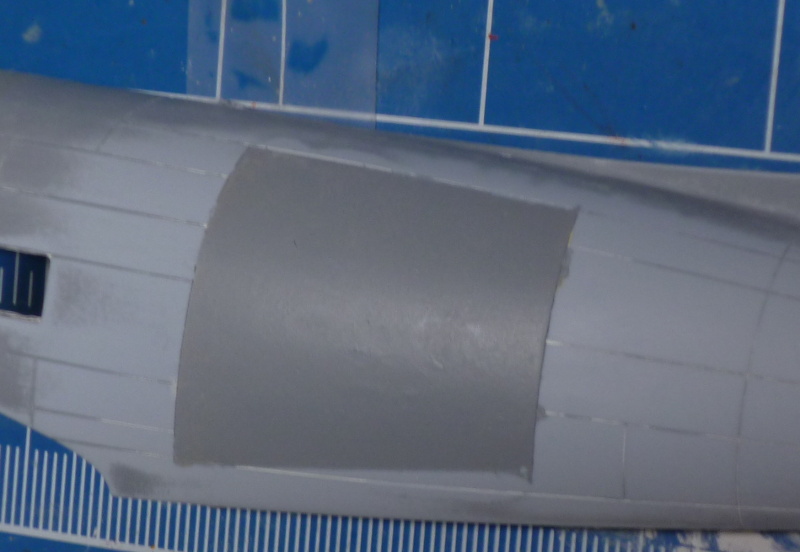

Martin R wrote:Aye, I have my own issues with scribing. So far, though, the '335's plastic has been very smooth and is taking scribing nicely. Although clearly I'm not scribing through filler...

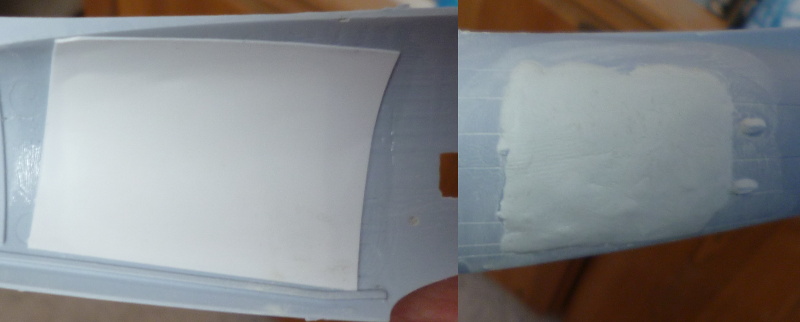

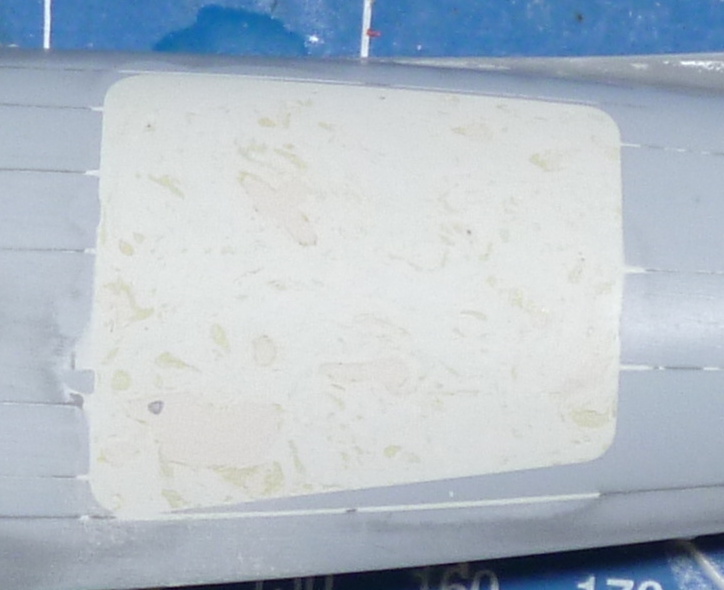

So far, the chosen tooling seems to be bearing up. I've finished the easy bits, that is, repair of the original panel lines around the door, and extension of any existing lines that simply cross the new panel.

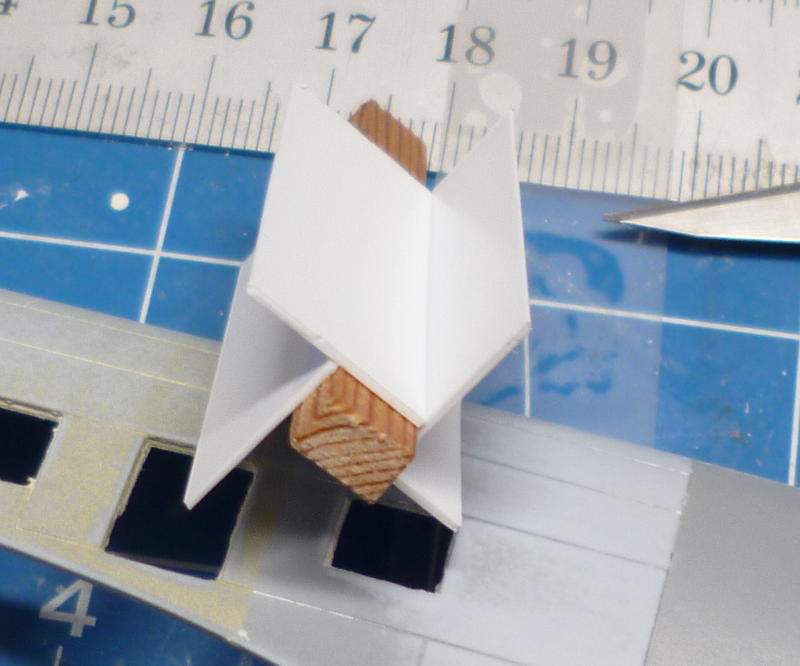

For those interested, the business ends of my scribing tools:

I'll be adding at least one extra window to the left side of the plane. Airfix have chosen to include the window frame on the transparency (good call, this will absorb any minor cracking when removing the parts from the sprues, but for this conversion, it creates a problem. For obvious reasons, there are enough windows, but no more than that. The newly created windows will therefore be different from the kit supplied ones, which will show. Obvious solution is to make

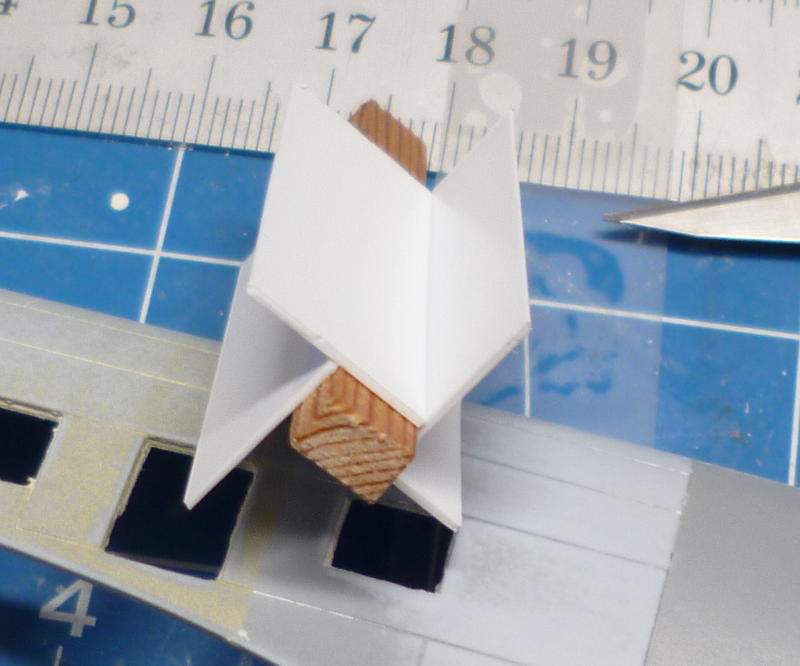

all windows the same, either from clear sheets, or from Clearfix or some such. But that in turn means I'll need the window frames in the original windows (I could simply cut the extra's a little smaller). Cutting out the window from the frame on the kit supplied parts does not appeal to me. The alternative is to make the actual window frames myself. Enter a piece of wood of the correct dimensions for the actual window, and some plastic card of appropriate thickness:

The 'wings' have by now been removed. To my relief, I got the size right; the plastic lines up nicely with the holes in the fuselage. Now, I'll have to cut thick slices from this bar, and hope I can get the wood out.

Even if this works out, it doesn't work for the emergency exits, as these are a bit wider. I'll have to cut out the window after all for those two parts.